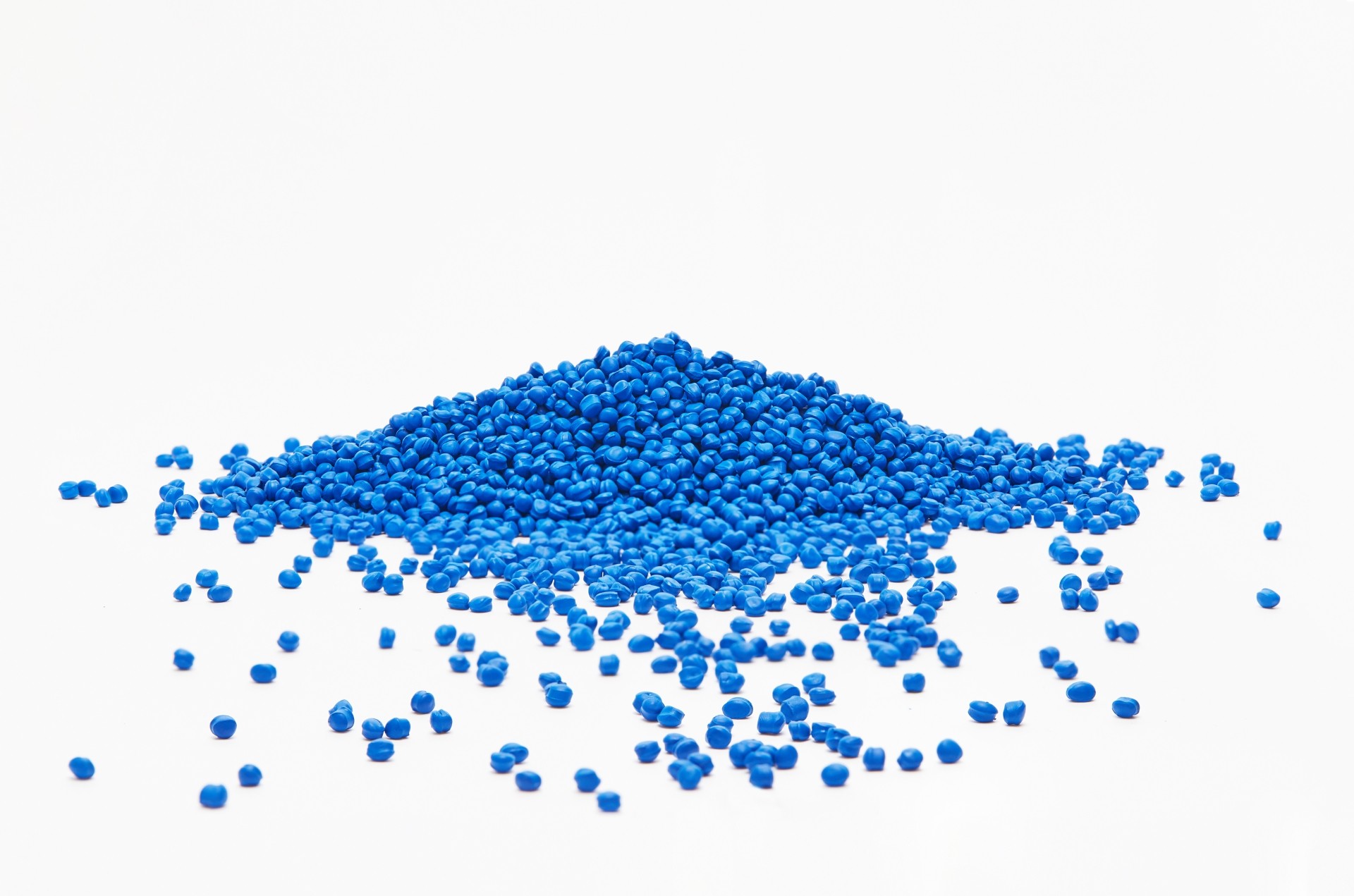

The Teclene® range comprises several types with different characteristics for general purpose, high fluidity, flame retardant, high impact, mineral filled and fiberglass reinforced.

All products are available natural and coloured to sample, RAL, NCS, PANTONE, special effects, metallised, glitter, pearly, and with different additives, such as antistatic, anti-UV, antibacterial and more.

The great versatility, excellent resistance to chemicals, low specific weight, good shock and wear resistance and simple transformation of Teclene® make it suitable for applications in several fields, such as: electrical and electronic, automotive, household appliances, household goods, toys, furniture and many technical applications.

Code

Description

Product Sheet

Certifications

Code

Description

Product Sheet

Certifications

Code

Description

Product Sheet

Certifications

Code

Description

Product Sheet

Certifications

When processing Teclene® the following transformation conditions are recommended:

–Cylinder temperature 180°C to 230°C;

–Mould temperature 40°C to 60°C;

–Dehumidification 1-2 hours at 50/60°C.

Any waste from processing can be re-used after grinding; the user must check suitability according to the application for which it must be used.

Teclene® comes in several types of packing: 20-25kg paper or plastic bags, 1000kg octabins or big bags. We advise storing the product indoors, away from humidity and sources of heat.